PET DTF Film

Leading DTF PET Film Manufacturer and Supplier in China

Wellye is a leading manufacturer and supplier of DTF PET Film in China. Wellye has been focusing on digital printing consumables for many years, specializing in the manufacture and sale of DTF FILM, PET Film, thermal sublimation paper, DTF transfer paper, thermal transfer paper and other digital consumables. Our products are exported to many overseas countries and are well received by customers all over the world. We can supply DTF Film in various specifications and offer customization service and samples. If you have any needs, you can contact us immediately!

Products and services we can provide

-

Better quality products

Shaking powder is cleaner, more convenient to use, and can be torn off immediately after printing

-

Free sample

All samples are free, you only need to pay the shipping fee to receive the samples

-

No MOQ

No matter the order size, sold in one pack

-

Factory price

We have our own DTF PET film factory, all products can offer ex-factory price.

-

Fast delivery

Ships within a week of receiving the order

High Quality DTF PET Film Products

We offer DTF Supplies in various specifications, including:

-

DTF PET Transfer Film Roll

-

DTF PET Transfer Film Sheet

-

DTF Ink

-

DTF Powder

About DTF PET Film

One of the benefits of DTF PET Film for DTF printing technology is that it allows you to use any type of fabric, not just cotton.

DTF PET film printing offers you greater flexibility as you can print on a range of fabrics including cotton, polyester, rayon, nylon, silk, leather and more.

Capable of producing fast and long-term full-color transfers for clothing and textiles, regardless of color or composition, DTF works perfectly with cotton, polyester, leather, softshell fabrics, all-around performance fabrics, bead ground blends, canvas, denim, and many more.

DTF PET Film Features

-

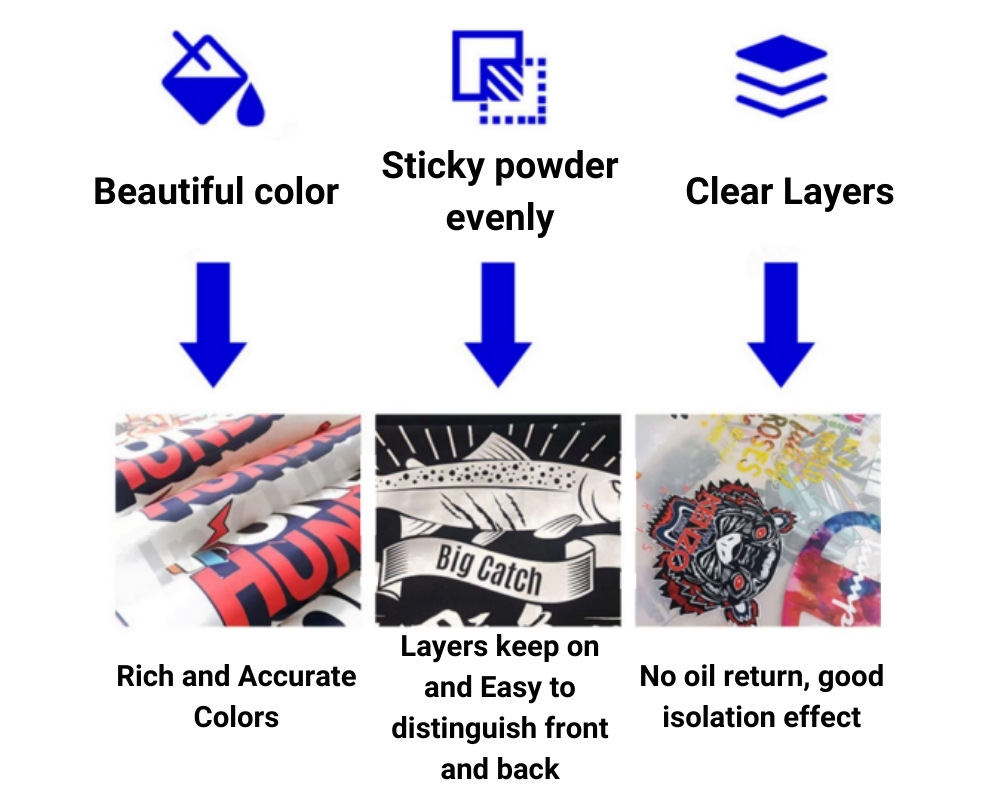

Vibrant and saturated colors

-

Cold and hot tearing available

-

Good ink absorption

-

No holes, air bubbles

-

Easy to peel, easy to shake powder

-

Excellent physical and mechanical properties

-

Low shrinkage, high temperature resistance

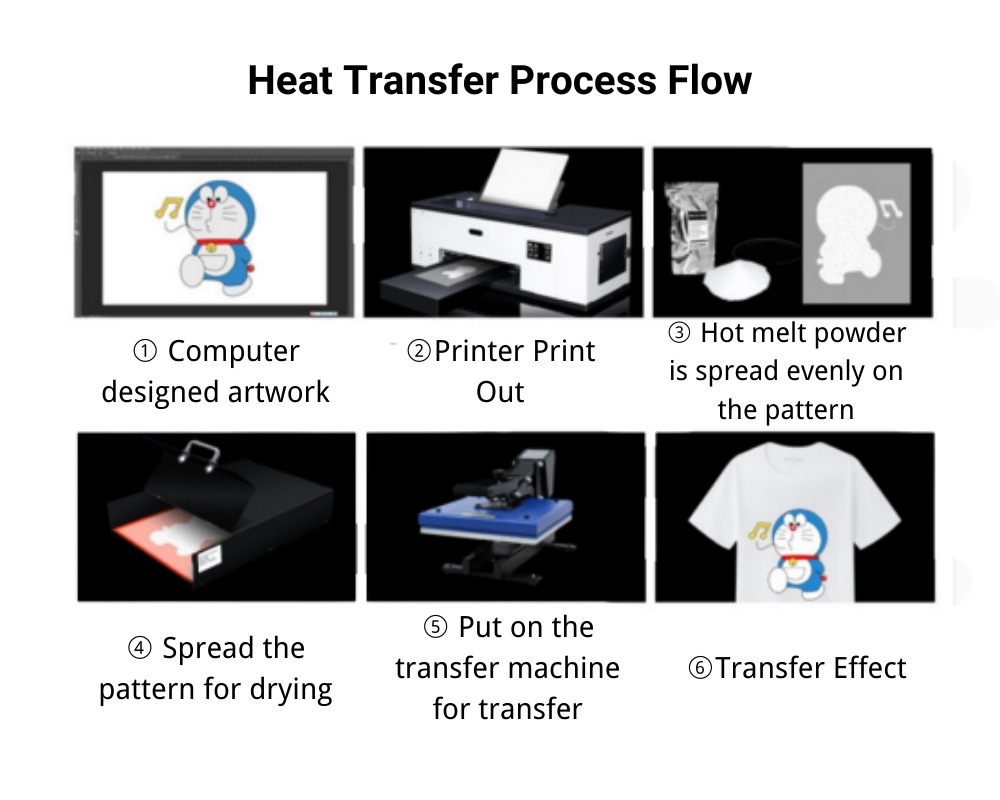

DTF Process Flow

DTF Printing Allows You To Create

-

T-shirts.

-

Pockets on hoodies or shirts.

-

Hats.

-

Shorts/pants.

-

Flags/Banners.

-

Koozies.

-

Any other fabric items.

DTF Effect Display

Why Choose Us

-

Our DTF Film is of high quality and meets national quality standards!

-

Our production cycle is short, delivery is fast, and the price is more competitive!

-

We can accept MOQ and support customized service!

-

We are sure to make you 100% satisfied, please give us a chance!

CHOOSE A PROFESSIONAL DTF PET FILM MANUFACTURER

As a top DTF PET Film manufacturer in China, Wellye has more than ten years of experience in the production of heat transfer paper, heat transfer paper, protective paper and DTF ink. Our service team has extensive experience in the digital thermal transfer industry. They will provide you with a comprehensive digital printing solution and work with you to find a balance between your requirements and costs.

With pre-sale and post-sale assistance by phone or email, our service team will provide you with timely support. We will be your reliable long-term partner.

If you have any questions or need customized services, please contact us immediately and we will give you the best solution!

DTF PET Film FAQ Guide

1.How to save DTF PET Film?

-

storage method:

To protect unused transfer film, it is recommended to store it in its original packaging, in a plastic bag at 68°F -82°F (20°C -28°C) and 40-60% RH.

-

Storage environment:

Relative humidity 35-65%, temperature 10-30°C, sealed indoor storage, avoid direct sunlight.

2. What should I pay attention to when printing DTF or DTG?

The image side wraps around the outside of the paper. Allow printing ink to dry before transferring.

-

Use process:

Double-head printing: After the color printing is completed, it is recommended to recycle the white ink to ensure the smoothness of the ink.

The pattern is directly digitally printed on the film - sprinkle hot melt powder - shake powder - dry melt powder - hot pressing.

-

Washing precautions:

-

We recommend washing transferred T-shirts separately with regular detergent and cold water.

-

Do not mix with other clothes.

-

Do not dry clean or bleach.

-

Dry immediately after washing. Or dry in a dryer.

-

After washing, if the image shows signs of peeling, you can cover the image with oiled paper and iron again. Do not iron the transfer unit directly with an iron.

3. What can DTF be applied to?

DTF can be applied to a variety of materials including cotton, nylon, treated leather, polyester, 50/50 blends, and more (light and dark fabrics).

4. Which is better, DTG or DTF?

For small-scale prints where you're looking for good color results and don't want to make such a large investment, DTF may be a better fit. But DTG now has more versatile presses with different plates and processes for faster and more flexible printing

5. Can DTF be transferred to wood?

To be able to customize on wood using DTF technology, you must have the following: DTF film: DTF film is a new technology that is easier to work with than t-shirt transfers and more environmentally friendly than Eco-solvent printable vinyl.

6. Is DTF printing environmentally friendly?

All PET films used by DTF are produced in an environmentally friendly and ethical manner. In some cases, using PET is made in a way that is recyclable./p>

7. What kind of printer does DTF need?

These printers are often referred to as DTF Modified Printers. Most of these printers are basic 6-color cartridge printers such as the Epson L800

8. Is DTG better than sublimation?

DTG printing is the best fabric printing machine for natural fibers like cotton, linen, canvas or jeans. Even darker materials produce high-quality prints. Sublimation printing is best for objects with polyester or polyester coatings.

9. Which is better DTF or vinyl?

Because the texture comes from vinyl, thermal transfer vinyl prints will always have a "rubber" feel. In the case of mass production, DTF printing technology outperforms thermal transfer vinyl printing technology in terms of workflow capability, throughput, efficacy and efficiency.